Archibiotect Vincent Callebaut designed a mixed-use residential building in Cebu City, Philippines, inspired from the local Rainbow Eucalyptus. At a time when radical solutions are needed to reduce the global carbon footprint, the architect designed a 32-story, 115-meter high tower built of solid wood, as it is the only natural, abundant, and renewable material integrating the principles of passive bioclimatism and advanced renewable energies.

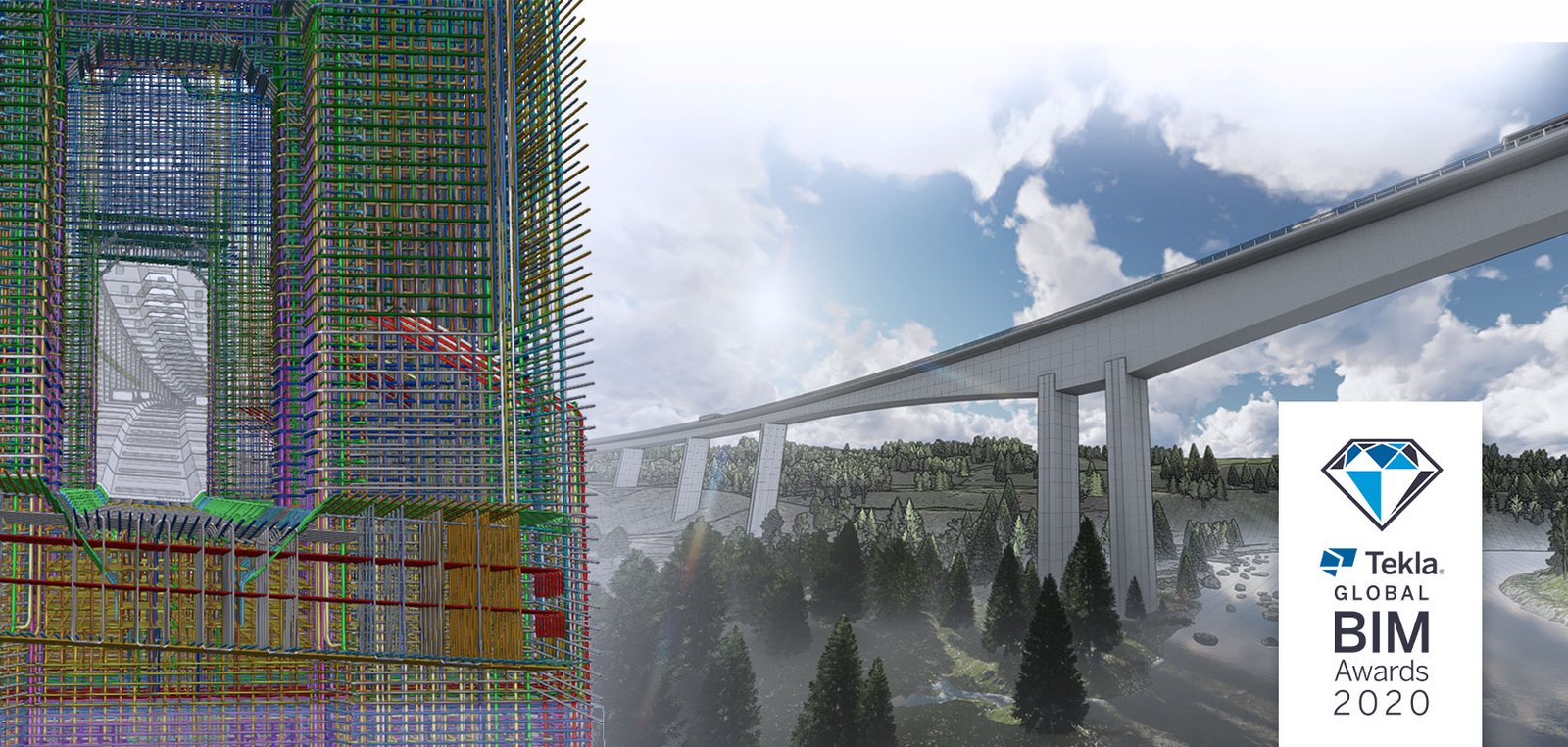

The Rainbow Tree tower is a 1,200-module staggered geometric stack with sides of 4 meters and a height up to 4.8 meters. All of these mass prefabricated timber modules are constructed with extreme accuracy at a factory. The material used for these modules is CLT (Cross Laminated Timber), the very same material used in Mactan Cebu International Airport and Clark International Airport New Terminal.

Cross-laminated wood originally introduced in Europe around 1990s, then spread to the United States and other parts of the world. The material has shown to be effective in a variety of building types, from low-rise to high-rise. In comparison to concrete and steel, it has also demonstrated competence in terms of strength, speed, and affordability. However, the CLT’s major selling point is that it is a sustainable building material, which offers it a distinct advantage over conventional solid building materials.

Although CLT is a type of engineered wood, there are several advantages of cross-laminated timber over other engineered wood-based products. CLT has even outperformed concrete and steel, the world’s top two construction materials. Here are a few of the benefits:

- Its panels are made up of cross-grain layers, making them less prone to deformation when exposed to moisture.

- CLT walls, floors, and roofs may be prefabricated off-site and then constructed on-site, saving time and money.

- Custom-shaped CLT panels, such as those for window or door apertures, may be made with CNC machines.

- Pre-fabrication of CLT panels also has the benefit of speeding up the construction process. Building an 18-story structure might take as little as 9 weeks.

- CLT may be molded into a variety of shapes including curved forms. If the thickness to length ratio is low, they can be bent during the manufacturing process or pushed on site.

- The amount of energy required to make CLT is half that of concrete and less than 1% of that for steel.

0 Comments